Original URL: https://www.linkedin.com/pulse/optimizing-eco-quality-gof-vs-conformal-methodologies-heidi-zheng-zlhec/

In the process of functional netlist ECO, there exists a crucial distinction between the Implementation Netlist and the Reference Netlist. These two netlists can either share the same hierarchical structure or exhibit discrepancies in their hierarchy. However, it's important to note that even if their hierarchies differ, they may still possess equivalent logic functionality. This equivalence stems from the fact that the flip-flops within unmatched hierarchies can be mapped in a one-to-one correspondence despite their differing hierarchical placements. In other words, regardless of the organizational arrangement of components within the netlists, the logical operations they perform can be aligned in a manner that ensures functional equivalence, thus maintaining the desired operational integrity of the circuitry being modified or optimized through the ECO process.

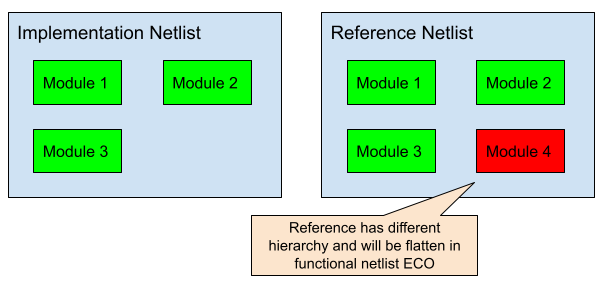

Consider the scenario depicted in Figure 1, where the Reference Netlist exhibits an additional hierarchical structure termed "Module 4" compared to the Implementation Netlist. To address such design complexities, the process of GOF ECO employs a strategy to streamline the Reference Netlist by flattening the hierarchical Module 4. This flattening process simplifies the netlist structure, facilitating a more direct comparison with the Implementation Netlist.

Figure 1: The Reference Netlist has different hierarchy

Subsequently, the task involves identifying all unmapped flip-flops present in both the Implementation and Reference Netlists and establishing a one-to-one mapping between them. Each successful mapping of these key points enhances the overall quality of the ECO process. This is particularly significant because in the worst-case scenario, if all flops within Module 4 necessitate the creation of corresponding new flops in the Implementation, it could lead to increased complexity and resource utilization. Therefore, the identification and mapping of unmapped flops contribute to optimizing the ECO process by minimizing the need for additional resource allocation and ensuring the efficient alignment of functional logic between the two netlists.

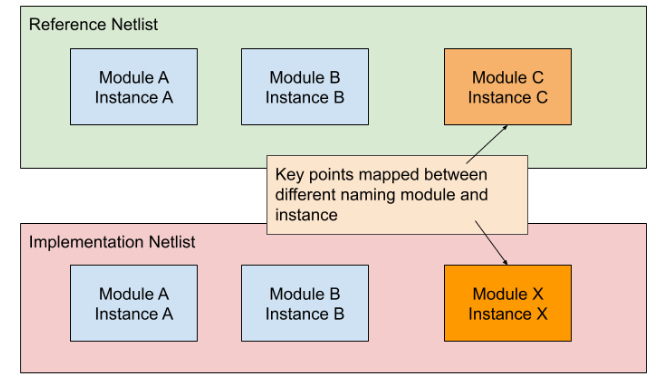

In other ECO cases, there are instances where the hierarchical module names and instance names differ between the designs being compared. In such cases, GOF ECO employs a similar approach to what was described earlier: it flattens any unmapped hierarchy to streamline the comparison process. Additionally, GOF ECO diligently endeavors to map all unmapped flip-flops between the designs.

Figure 2: Different Hierarchical Module and Instance

This meticulous approach is aimed at achieving the highest possible ECO quality. By ensuring that all relevant components are properly mapped, GOF ECO optimizes the functionality and performance of the modified design. This dedication to thoroughness distinguishes GOF ECO from competing methodologies, such as Conform ECO.

On the contrary, Conform ECO may occasionally encounter errors, indicating that "The non-equivalent hierarchical design instances fail to map," when it encounters unmapped hierarchical instances. This error can lead to the failure of the ECO process, prompting customers to either abandon their ECO efforts altogether or restart the design process entirely. Such setbacks inevitably result in delays to the project schedule, causing inconvenience and potential disruption to planned timelines.

GOF ECO's commitment to enhancing ECO quality is evident in its proactive exploration of various techniques, including addressing unmapped hierarchy scenarios. This unwavering dedication to improving ECO quality underscores its value in meeting the needs and expectations of customers, ensuring that their designs are optimized for performance, functionality, and reliability.

GOF platform integrates four functional components: ECO, Formal, LEC and Debug. To access detailed information about GOF, please visit the website https://nandigits.com